Low casting speed

If the first poured liquid flow has solidified into thin shells which will inward contraction, then poured liquid flows will get into the gaps between the thin shell and the refractories mold which form scar on the surface of fused cast series block. Meanwhile, if the liquid flows are too thin, before reaching the side corner the liquid flow will be solidify which will lead to Insufficient casting. In addition, low casting speed will also lead to long time casting which means that mold baking time will be increased, that the mold cover is easy peeling off into the molten liquid and cause sand inclusion.

High casting speed

If the Changxing refractory castable speed of fused cast series block is too fast, the liquid flows become wide which bring a great impact on the casting mold of fused cast series block, then part of casting mold is broken through or melted which can make this part of mold risen up. In addition, when the wide liquid flow is casted into mold, some air is may brought into casting mold and rising to the top cover of the mold rapidly. Meanwhile, liquid touched top cover has already formed thin shell, so when air rises to the top cover that so-called shell is formed. What is more, it is easy to form air bubbles inside the mold when air is brought in mold. Except for the air, wide liquid flows caused by high casting speed may also brings the raw material which is in furnace mouth into molten liquid of fused cast series block.

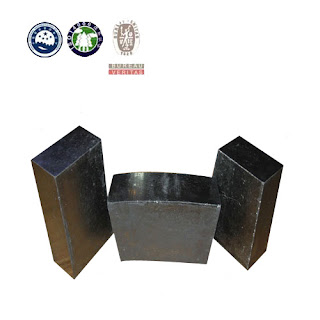

China Xinmi Changxing Refractory material Co., Ltd. our product portfolio covers shaped products such as refractory brick for sale,refractory castable, refractory nozzle, ceramic fiber, slide gate, etc;

没有评论:

发表评论